Jones Snowboards introduces new Re-Up technology

Popular Stories

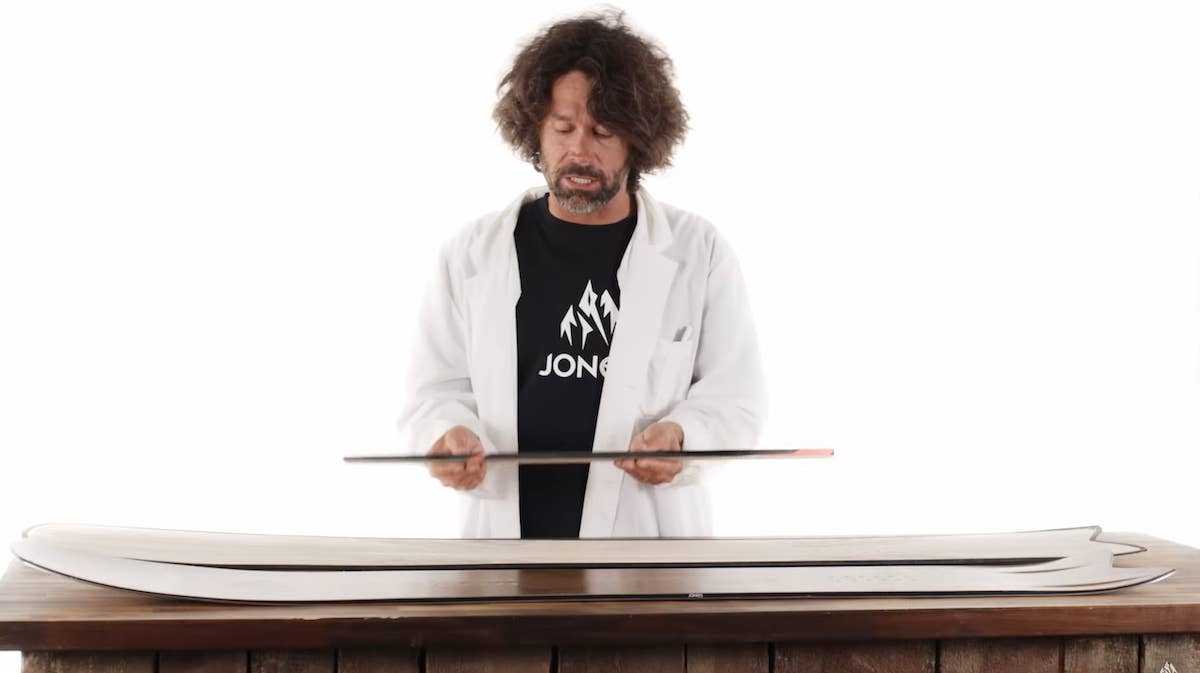

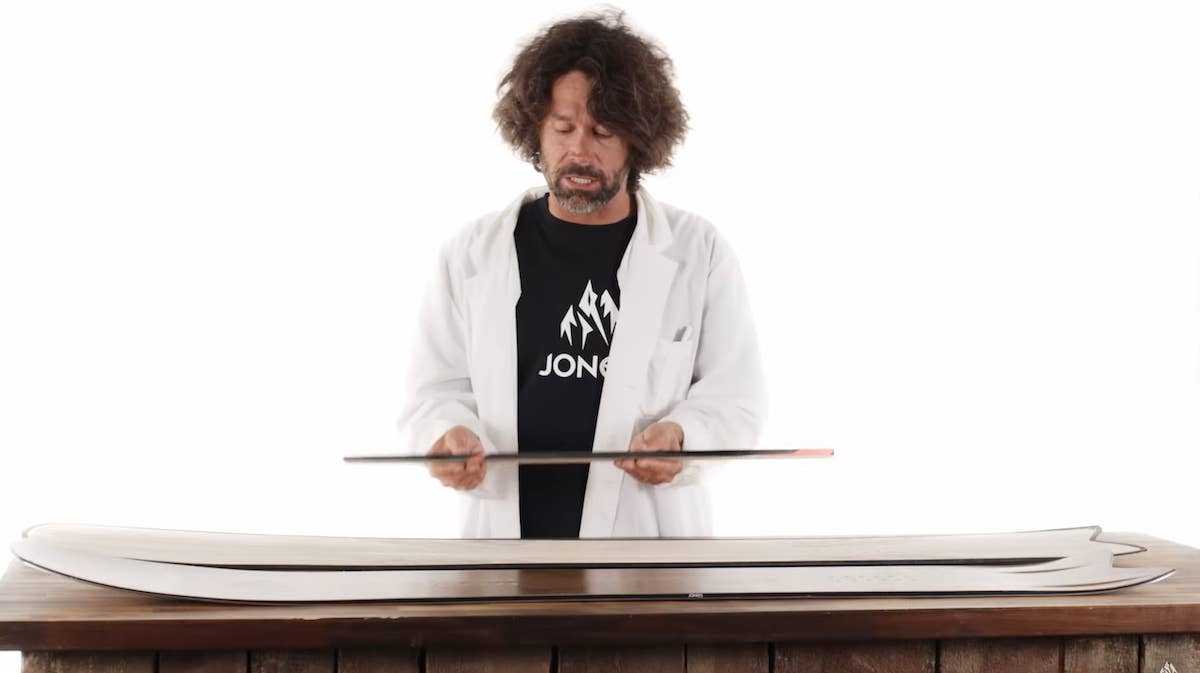

Big mountain snowboarding legend and the mind behind Jones Snowboards, Jeremy Jones, is very excited to introduce their latest in snowboard construction from the Tech Chamber, Re-Up Tech.

Re-Up Tech means recycling old snowboards and upcycling the materials to construct new snowboards. Jones is proud to say they are able to use 95 percent of an old snowboard through this process. To start, all the me medal in the edges and inserts get removed and recycled. Now without the edges and inserts, the board is essentially a sandwich of p-tex, epoxy, wood core, stringer material and top sheet. This "sandwich" is then flattened in a press to remove any rocker or 3D contours. Then, six flattened boards composed of any brand or material composition get stacked, glued and pressed together to create a 24-layer thicker sandwich that includes six layers of p-tex, six laters of wood core,six layers of stringers and six layers of topsheet material.

Sign Up For Our Newsletter

The sandwich is then cut into thin slices that include all 24 layers of recycled material. The thin slices are what are inserted as "performance stringers" in the construction of new wood cores. These stringers create an incredibly strong section of the new board, eliminate the use of new carbon, absorb vibration, are more torsionally stable than any stringers Jones has tested, and may even hold stories and secrets from board's past.

For this season the Hovercraft 2.0 is currently the only board in the Jones lineup with their new Re-Up technology. The Re-Up technology combined with the flax topsheet and recycled edges and sidewall make this board the most sustainable board Jones has ever produced and technology they hope to bring into the rest of their lineup