Results 26 to 43 of 43

Thread: SkiScribe Centerline Tool

-

10-11-2021, 10:51 AM #26

Any plans for more of these? Just did a few skis and found myself really wishing I had something like this to speed things up.

-

10-11-2021, 12:16 PM #27

Would be interested as well if another run happens. I don't own any jigs and have used the "traditional" centering technique for paper jigs on the dozen mounts over done.

Have 2 more coming up this fall so anything to make it quicker/easier is welcomed!

(anyone selling a solly jig?? )

)

-

10-11-2021, 12:50 PM #28

I've got a narrow soli jig hiding somewhere in my basement.

-

10-11-2021, 02:16 PM #29

If these where made out of metal, with steel dowel pins, I could be interested. The problem I see with this design is those wooden dowels are going to start to wear quite quickly against the steel edges of the skis, destroying its accuracy.

-

10-12-2021, 06:56 AM #30

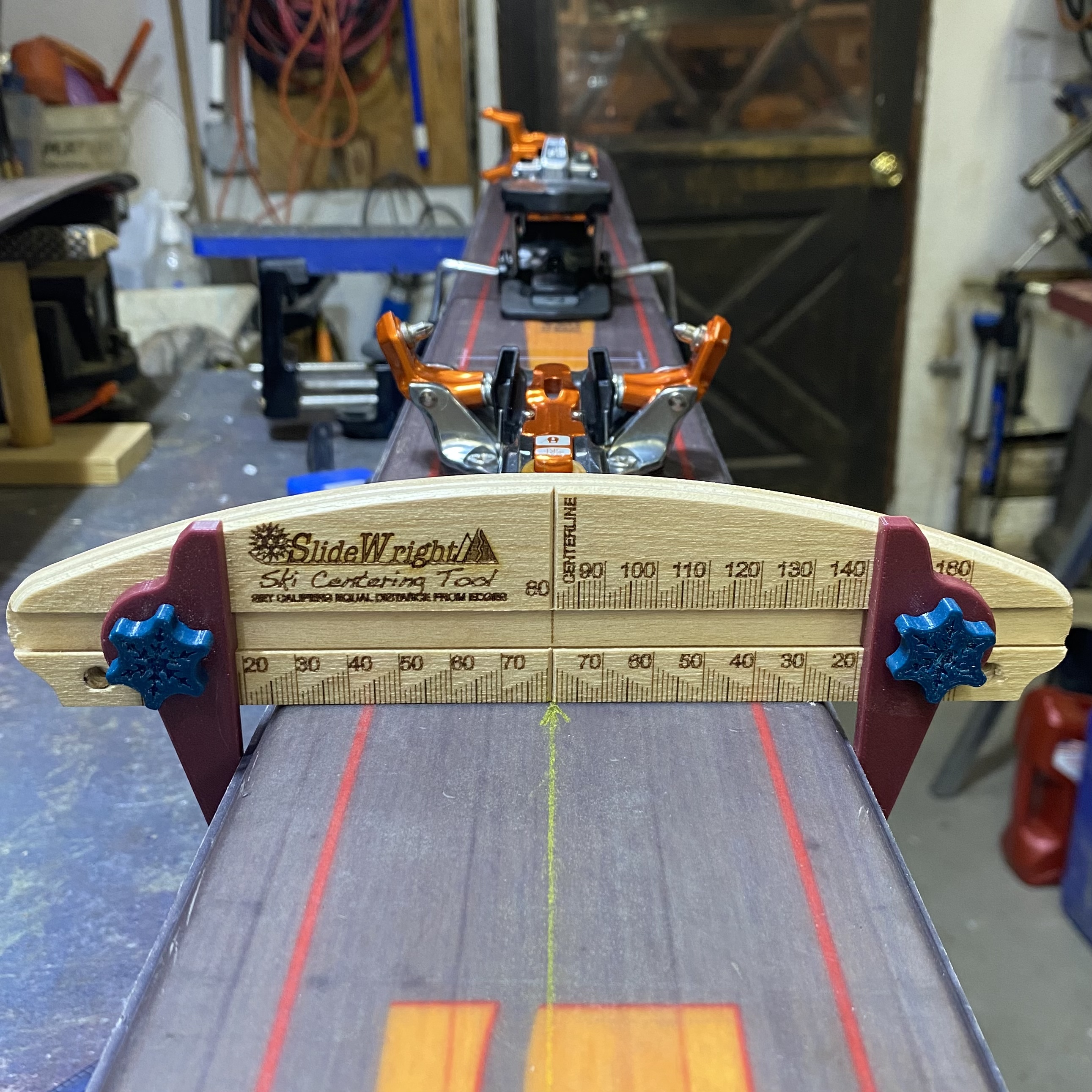

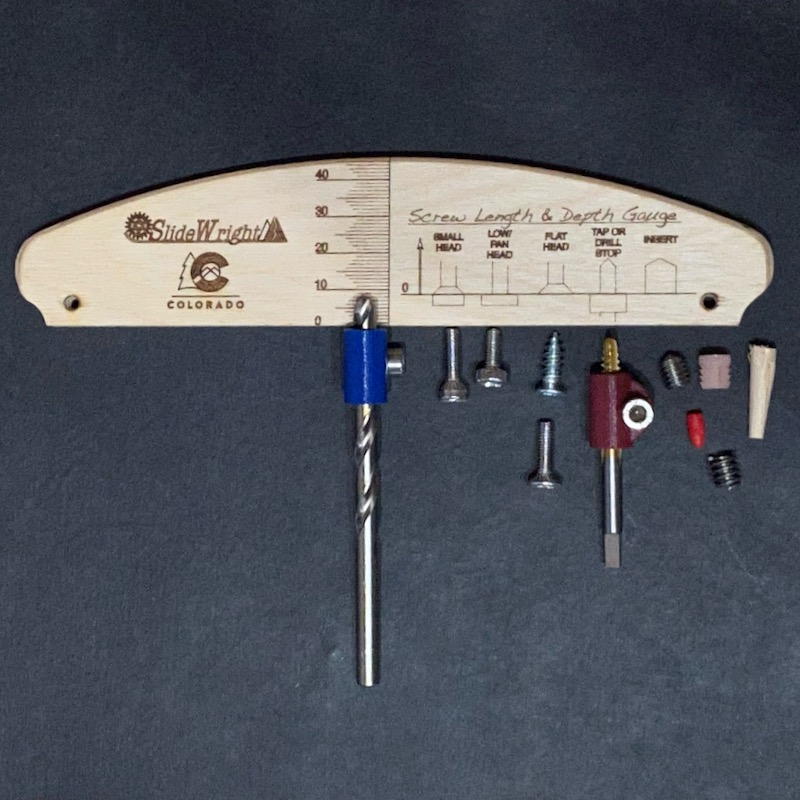

Not in the foreseeable future as we are slammed on several fronts. I changed the design and we did a run in a window I had to do this, but ended up shelving them because I wasn't pleased with their accuracy after CNCing and lasering. I do hope to circle back sometime this winter.

I seriously doubt that hardwood dowels will 'wear out quickly' along a ski edge unless your edges are burred like crazy. The intended use is for a a few passes along skis for the typical DIYer, not for doing thousands of mounts. Regardless, after making a few ticks or scribes, you use the tool to double check the marks. I considered metal pins, but keeping it wood and working with wood is part of the appeal for us.

Big storm hitting us now!Best regards, Terry

(Direct Contact is best vs PMs)

SlideWright.com

Ski, Snowboard & Tools, Wax and Wares

Repair, Waxing, Tuning, Mounting Tips & more

Add TGR handle to notes & paste 5% TGR Discount code during checkout: 1121TGR

-

10-12-2021, 10:17 AM #31

Just a note.

I've always hated monkeying around with finding the centerline, and drawing a line on tape down the ski. (It's one of those trivial annoyances - it probably only takes a few extra minutes. But for me, it's a real irritation - probably one of the reasons I'd have for putting off doing a mount for another day.)

So, I was looking to find a better way. This looked to be the best I could come up with.

I thought I'd 3D print something.

Looked on thingaverse - but the ones I saw kinda sucked. Too narrow. The pins that stick down were too short. (They'd end up riding on the sidewalls, not the edges. So I designed my own. Very similar to Terry's.)

I think the accuracy is pretty spot on.

(You have to be careful to keep the pins snugged up on the edges of the ski.)

But it's very fast, and way easier than any other method I've tinkered with.

Terry's looks nice. Way prettier than mine.

(But if you discount the cost of the printer and my design time cost, mine was way cheaper. LOL)

The TLDR version is; This method is, IMO, way more than accurate enough, quick and irritation free.

10/10 would recommend.Last edited by gregorys; 10-12-2021 at 10:55 AM.

-

10-12-2021, 10:36 AM #32

-

10-12-2021, 11:26 AM #33

You see this thing:

https://www.thingiverse.com/thing:4744005

I've been using it for the past ~ 4-5 mounts on my skis and its worked great. Also printed a couple for some mags here too."Poop is funny" - Frank Reynolds

www.experiencedgear.net

-

10-12-2021, 12:39 PM #34

-

10-12-2021, 12:50 PM #35

More than a few times, I've wished for a capable 3d printer for prototyping or simply producing tools and other stuff. Where to even start getting up to speed on all of the options, costs & gauging ROI's? As much as I prefer wood or metal over plastic, the centerline tool would be easier to produce with a 3D printer vs the CNC & laser approach. A batch of tools could take eons, however.

I think Jill at Purl told me they have (3) 3D printers running in the background almost continuously to produce their scraper sharpeners.Best regards, Terry

(Direct Contact is best vs PMs)

SlideWright.com

Ski, Snowboard & Tools, Wax and Wares

Repair, Waxing, Tuning, Mounting Tips & more

Add TGR handle to notes & paste 5% TGR Discount code during checkout: 1121TGR

-

10-12-2021, 12:58 PM #36

-

10-12-2021, 02:21 PM #37

Dude they're pretty cheap and quiet these days ~ $300 ish for a decent quiet one off the Zon. The 3 printers I have are probably the most common tool I use in my house. Need a bracket for hanging speakers - done, drill jig for mounting cabinet handles or mounting skis - done, topo maps for BC route finding and planning - done. I do caveat that statement with the fact that I work as a design engineer - so mocking stuff in CAD is pretty quick for me....

Shoot me a PM we'll get it sorted out."Poop is funny" - Frank Reynolds

www.experiencedgear.net

-

10-12-2021, 02:34 PM #38Best regards, Terry

(Direct Contact is best vs PMs)

SlideWright.com

Ski, Snowboard & Tools, Wax and Wares

Repair, Waxing, Tuning, Mounting Tips & more

Add TGR handle to notes & paste 5% TGR Discount code during checkout: 1121TGR

-

10-12-2021, 02:55 PM #39

-

10-12-2021, 03:02 PM #40

In our middle school the required 6th grade Engineering Class has kids programming (simple) 3D printer projects. They can move on from there up through HS depending on interest. I see this diy industry blowing up in the next decade or so!

-

10-12-2021, 03:47 PM #41

I would say most people that I see charging for parts made on FDM printers are doing it on a specific material price standpoint. For the few items I sell, I primarily look at it from a machine time + comparative costs + what I think is a reasonable number in order to come up with a cost estimate. Realistically, the filament is pretty cheap ~ $20 per spool when bought in bulk, but machine maintenance and my time is way more valuable than that - hence why I don't really account for it, unless its a more exotic material like PC.

From what I am seeing, I would give it 5. Already starting to see more and more parts printed being sold on amazon. Also saw a couple years back Tesla was having printed parts on all their cars for a bit while they were waiting for production tooling. From what I see, the biggest limit right now is needing to babysit a single printer when doing a production run. There's a couple of belt-bed style printers that will just run until the cows come home, as well as some interesting firmware that folks are doing to implement a bed clearing operation after the initial print is done. As soon as that becomes more consistent, it will most likely put short to medium injection molding production runs out of business."Poop is funny" - Frank Reynolds

www.experiencedgear.net

-

10-12-2021, 04:11 PM #42

Registered User

Registered User

- Join Date

- Nov 2019

- Posts

- 122

I have the Dremel digilab 3d printer and it was super simple to setup and use, I was very surprised at how user friendly it is. I use fusion360 and there are a ton of youtube videos to help you learn the program, the Lars Christensen beginner videos made it really easy to get the hang of fusion and it is free so you could just download it before you get a printer and see if it is something you want to pursue. Other than the printer everything else is pretty cheap(filament is about $25 a roll), the main issue with 3d printing is it can take along time to print bigger models. We manly use our printer for rough prototyping then use a print house that can do higher quality printing methods for the final.

-

03-03-2022, 08:55 AM #43Best regards, Terry

(Direct Contact is best vs PMs)

SlideWright.com

Ski, Snowboard & Tools, Wax and Wares

Repair, Waxing, Tuning, Mounting Tips & more

Add TGR handle to notes & paste 5% TGR Discount code during checkout: 1121TGR

Reply With Quote

Reply With Quote

Bookmarks