Would it be possible to build some sort of universal jig that holds paper templates?

Results 26 to 50 of 75

-

01-20-2012, 03:25 PM #26**

I'm a cougar, not a MILF! I have to protect my rep! - bklyn

In any case, if you're ever really in this situation make sure you at least bargain in a couple of fluffers.

-snowsprite

-

01-20-2012, 03:30 PM #27

-

01-20-2012, 03:32 PM #28

-

01-20-2012, 03:38 PM #29Best regards, Terry

(Direct Contact is best vs PMs)

SlideWright.com

Ski, Snowboard & Tools, Wax and Wares

Repair, Waxing, Tuning, Mounting Tips & more

Add TGR handle to notes & paste 5% TGR Discount code during checkout: 1121TGR

-

01-20-2012, 03:49 PM #30

there you go!

great idea... how about putting in some kind of slider bar so they can be positioned to BSL? I guess it'd be easy enough to DIY that part.

Here's a problem though, I'm comfortable with paper templates so I really wouldn't pay extra for that - but maybe people would? I'd have to put the total DIY outlay at probably 2x shop mounts - so if you could get everything you need for $80-100 that'd be a good start.... jfost is really ignorant, he often just needs simple facts laid out for him...

-

01-20-2012, 04:06 PM #31Best regards, Terry

(Direct Contact is best vs PMs)

SlideWright.com

Ski, Snowboard & Tools, Wax and Wares

Repair, Waxing, Tuning, Mounting Tips & more

Add TGR handle to notes & paste 5% TGR Discount code during checkout: 1121TGR

-

01-20-2012, 04:13 PM #32

well, there shouldn't be an inaccuracy - the paper templates thread has a certain amount of risk tolerance built in, but maybe that is the beauty of paper, nobody who is truly clueless will touch it?

There hasn't been a problem to my knowledge in providing the drill bits or countersinks etc. I really don't think people who would be inclined to use these products would be the type to go after new skis from you... that is unless your jig is flat out wrong or off! There's a reason smart people test out these things on a 2x4 1st!... jfost is really ignorant, he often just needs simple facts laid out for him...

-

01-20-2012, 04:30 PM #33

jfost's price range is about what I was thinking. I'm pretty comfortable with paper templates, but I think a plastic jig could potentially speed the process up, especially if there was some sort of slider bar to help align them for different BSL's (something similar to the hash marks on the paper templates).

For me to buy the jig, I'd want:

-compatibility with Salomon, Look/Rossi, Dukes, Jesters, Dynafit, and maybe some of the others - Fritschi, Tyrolia, etc.

-color coded holes so that I'm drilling into the correct holes for the binder I'm mounting

-hash marks to help align the jig with the center line of the ski

-hash marks or a bar to help align the jig for various BSL (both relative to the mounting point on the ski and to the heel section of the jig)

If it had all of that, I'd probably pay around $50-75 for it just because it'd make mounts pretty easy.

I wouldn't think there'd be too much liability with it. As long as the hash marks and hole spacings are all accurate, it'd really only be user error that would result in a botched mount. Make sure to include a good set of instructions with it.

-

01-20-2012, 04:52 PM #34

wow, just mounted a pair of Dynafits and despite being a ski mounting veteran I must admit I was a bit intimidated

looked around the basement where my bench is and noticed some wide masking tape - man, that stuff was handy - I used it as a straight edge for the centerline as well as to mark up the insert line, boot center, and heel line

would definitely encourage folks to get a roll before their next mount job

-

01-20-2012, 05:59 PM #35

Registered User

Registered User

- Join Date

- May 2005

- Posts

- 3,972

I'm your huckleberry. Been working on a system that addresses this. Have a few out across the wide world & demo / tests have so far come back good.

I'll get with Alpenord/Slide Wright and see if we can roll with it.

Be hard to get all the patterns in one due to hole overlap issues. Plus confussion overload.

If I could make pictures work on TGR these days I'd put some up.

Give me a bit to get some better pics/vid and figure out a place to host them.

In the mean time, here's one of my first one's with a Dynafit pattern.

-

01-20-2012, 06:08 PM #36Best regards, Terry

(Direct Contact is best vs PMs)

SlideWright.com

Ski, Snowboard & Tools, Wax and Wares

Repair, Waxing, Tuning, Mounting Tips & more

Add TGR handle to notes & paste 5% TGR Discount code during checkout: 1121TGR

-

01-20-2012, 06:33 PM #37

It seems like there are at least three 'need categories' for jigs, tools & guides:

1) Basic measuring and drilling aids

2) Universal jigs & guides

3) Binding specific templates/jigs

One thing that appears to be constant is that binding holes are either a single hole or a pair relative to a centerline:

Best regards, Terry

(Direct Contact is best vs PMs)

SlideWright.com

Ski, Snowboard & Tools, Wax and Wares

Repair, Waxing, Tuning, Mounting Tips & more

Add TGR handle to notes & paste 5% TGR Discount code during checkout: 1121TGR

-

01-20-2012, 06:38 PM #38

oh man, I like where this is going - how about a small guide that clamps to ski and can be adjusted width-wise to put 2 holes equidistant from centerline *anywhere* on the ski. Maybe have a center hole too for those that require it. You could theoretically cover ALL bindings with that one uber-adjustable tool!

Basically, you'd mark locations with a paper template, then slap this guy on, sight the holes and have a nice drill guide where you're sure that the holes are centered...... jfost is really ignorant, he often just needs simple facts laid out for him...

-

01-20-2012, 07:07 PM #39

-

01-20-2012, 07:22 PM #40

I too like where this is going.

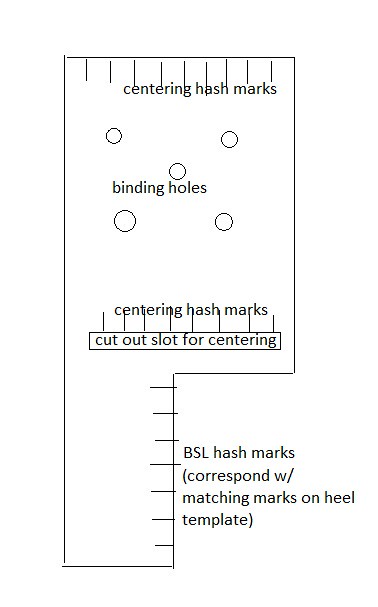

Here's a shitty MS paint depiction of what I was thinking:

this would be the toe half of the template. The heel would essentially be the same except flipped - the offset part would be at the top and on the right side so you could line up the corresponding BSL marks. The cut out slot is so you have top and bottom hash marks for centering (the offset parts make it so you can't really just do hash marks along the bottom edge).

Like FZ said, you probably wouldn't be able to get all of the different kinds of binders on one template due to hole conflicts, but you could probably fit a couple on one template.

-

01-20-2012, 07:25 PM #41

oohhh -- I really like the Idea of a universal type jig

I would gladly order that!

-

01-20-2012, 07:53 PM #42

I am your bumbling idiot test case.

The hardest part for me is not just getting everything lined up, but also keeping the screw holes in place. It's easy to misfire by a couple of millimeters. A simple multipurpose jig like described above by Zappa, with a hole pattern by Terry, would do the trick. Also, annotate the jig face with the expected screw depths. ohhh, i want one now.

From a marketing standpoint, if you could offer a mount kit with that jig plate, the two correct metric bits with collars, and the correct screw driver, simple set of fancy printed instructions, and those great online videos, that seems like it would be successful. A separate tap and countersink are somewhat optional and probably confusing to a lot of people, imo. I think you already have kits for the binding inserts.

btw, I do this because skiing is my hobby and I should own it. And I have seen shitty shop jobs. And it's fun and I'm a gear head. I've completed about 10 mounts using speed square, hand drill, stop collar, tape, and pencil. I got a good set of guidelines from a friend. No paper templates. I had one scarey moment up where I stripped two holes with the wrong depth screw. I patched by hammering in a trimmed wood dowel smeared with wood glue, later redrilled, and it works fine. My next mount will use paper templates.

-

01-20-2012, 10:29 PM #43

FrankZappa sighting!

FKNA, son! How you doing?I didn't believe in reincarnation when I was your age either.

-

01-22-2012, 02:05 PM #44

Had a brainstorm this morning. Lego based mounting jig.

The tolerances on lego pieces aren't quite tight enough to use for real, but this could be the basis for a self centering universal jig. I generally have no problem getting the relative location of the holes easily, it's getting them centered relative the ski that I have the most problems with.

-

01-22-2012, 05:49 PM #45

Registered User

Registered User

- Join Date

- Nov 2011

- Posts

- 2,835

The universal jig idea is good. But remember, Alpinord is dealing with customers that may need a lot of handholding. A plexi/lexan drill guide fo rthe most popular bindings (especially Salomon and Tyrolia because of their uniformity across models) might be cheap enough and popular enough to be worth while. It would have drilled holes, to serve as a guide, and have a center line, and BSL markings, looking very much like the paper templates posted here at TGR. The center line could be ethced or printed, but since you'd want to print things like Model ID, brand name, and BSLs, it might as well be printed. Printing can be done either by silk screening or by printing a clear decal/label and sticking to the drill guide. You'd need separate toe and heel pieces, and you could even print directions on the guide. I'd think you'd be able to produce these to retail at $20 or so. And although they'd really be no better than the paper templates, they'd offer psychological assurance to the noob mounter.

Another alternative, that could be offered dirt cheap, depending on licensing/copyright issues would be to print paper templates on clear sheet. Any ink jet printer can do this. The clear template would be slightly easier to use than opaque paper.

-

01-22-2012, 06:06 PM #46

-

01-22-2012, 11:21 PM #47

Yes, but there is a way around that. One way would require some additional pieces, but I think it could work. You can use the scissor part to place a square bar centered on the ski and then place a cross piece with holes of the required distance. If you make the bars long enough there is a reasonable chance one pair of the holes in the bar will match the width you want. A bit of math and you could move the central pivots to match the ski width and hole offset.

-

01-23-2012, 12:14 AM #48

not awesome

not awesome

- Join Date

- Mar 2011

- Location

- SW Jongistan

- Posts

- 451

-

01-23-2012, 01:40 PM #49

trenchman

trenchman

- Join Date

- Feb 2010

- Posts

- 4,547

i also like where this is going, having sworn off shop mounts since 08.

thanks for thinking

bobby

-

01-23-2012, 02:03 PM #50

Reply With Quote

Reply With Quote

Bookmarks