Results 4,476 to 4,500 of 6863

-

12-28-2020, 10:06 PM #4476

Thanks doods. Remounting the toe at -1. Heel has plenty of room.

-

12-29-2020, 07:28 AM #4477

-

12-29-2020, 09:48 AM #4478

Registered User

Registered User

- Join Date

- Mar 2008

- Location

- northern BC

- Posts

- 31,040

I use a 5/32nds, the world didnt end

but now we have covidLee Lau - xxx-er is the laziest Asian canuck I know

-

12-29-2020, 10:58 AM #4479

Registered User

Registered User

- Join Date

- Jan 2012

- Location

- Juneau

- Posts

- 1,100

-

12-29-2020, 01:03 PM #4480

-

01-01-2021, 01:35 AM #4481

Registered User

Registered User

- Join Date

- Jan 2020

- Posts

- 158

Mounting my DW with shifts worked great. Didn't land exactly on the mount line I was going for, but it's close enough.

Thinking about mounting my first pair of metal skis, commander 98s with Pivot 15s. If I got the shifts Ok these should be easy enough? I'm worried with less boot adjustment on the Pivots I might fuck something up, but maybe that does not make sense.

-

01-01-2021, 04:12 AM #4482

Registered User

Registered User

- Join Date

- Oct 2017

- Posts

- 2,304

just do a test mount on a piece of wood or retired ski ensuring that you land with the center mark on the recommended mount point aka in the middle of the adjustment range. Then replicate the process. It is pretty straight forward really.

Shifts and Pivots are very much similar wrt "difficulty" - that is, both are pretty nice to mount but require a bit of precision (if not all the way into tech binding precision to be sure) - and Knut's templates are pretty accurate, so I wouldn't worry.

Just do the test mount, measure everything three times and things should be fine.Last edited by kid-kapow; 01-01-2021 at 11:32 AM.

-

01-01-2021, 11:17 AM #4483

You’ll be fine. Let her rip. Just watch and learn. Each mount is easier than the last (in theory anyway).

-

01-01-2021, 04:31 PM #4484

Registered User

Registered User

- Join Date

- Jan 2020

- Posts

- 158

Sounds good. So what is the best way to measure the actual BSL of a boot? My XT3s 26.5 say they are 303 but if the mounting is this precise it would be nice to know. Is it tip of the locking lug to the tip of the other one?

And what size tap do you normally use? I didn't tap my DWs.

-

01-01-2021, 08:18 PM #4485

Quick question regarding re-using mounting holes. The last time I tried to do it (last week), I retapped the holes, but I probably fucked it up because I got two spinners. So I went QK's on it because I was planning to do that long term anyway.Well now I want to mount another pair up and I want to go over the process and make sure I'm doing it right.

Should I re-tap the holes? I have a tapered tap so it makes it harder to recut the same threads (easier to cross thread). I would think that the tap should just slide in, but I get resistance after a turn or so. Same deal with just threading the screws in raw. Goes smooth for a turn or two and then I get resistance.

Should I just screw the screws in without re-tapping and hope for the best? I would think it would be easy to thread them in all the way but it isn't. Seems strange, but maybe that's common.

-

01-01-2021, 08:22 PM #4486

lots of good tips here

https://www.tetongravity.com/forums/....php?p=6175984

-

01-01-2021, 08:29 PM #4487

Registered User

Registered User

- Join Date

- Mar 2008

- Location

- northern BC

- Posts

- 31,040

Lee Lau - xxx-er is the laziest Asian canuck I know

-

01-01-2021, 08:35 PM #4488

Yeah, the only thing is I don't have epoxy or fiberglass on hand and the holes feel pretty tight. Seems like I should be able to just remount virginally with some roo glue no?

-

01-01-2021, 08:46 PM #4489

Registered User

Registered User

- Join Date

- Jan 2012

- Location

- Juneau

- Posts

- 1,100

I would, and I wouldn't tap first. Not sure what benefit would come from tapping first. If the threads are still good, add some Roo glue, Titebond, or whatever you like and reinstall. If it snugs up tight, I wouldn't hesitate to ski it. If there are spinners, time to fix.

-

01-01-2021, 08:47 PM #4490

Registered User

Registered User

- Join Date

- Mar 2008

- Location

- northern BC

- Posts

- 31,040

then run whatcha brung

Lee Lau - xxx-er is the laziest Asian canuck I know

-

01-02-2021, 11:33 AM #4491

I've read through all (or at least most) of the mount & BF/QK threads, such great info. Two questions here, one really jong stupid, the second maybe jong-lite...

1) Am I right in that existing binding screws don't match the inserts threading, so you need the BF/QK screws?

2) Drill guides seem pretty damn helpful, especially for new holes. Is the BF one (pic) a good option? If I end up doing 5 or so skis (plus maybe friends if they trust me), $25 is nothing

Thx all

-

01-02-2021, 11:40 AM #4492

1. Yes. You need the M5 machine thread screws for BF or QK inserts

2. I've never used that BF tool but I personally would not do a BF insert job without a drilling guide of some sort. That seems to be a cheap and easy option for that job.

I'm not an expert by any means but I did do inserts in 5 pairs of skis this year for the first time, and I don't trust myself to drill straight at all, at least not for inserts.

Also I found a tap guide to be extremely helpful.

Sent from my Pixel 4 using Tapatalk

-

01-02-2021, 11:42 AM #4493

I use the BF punch for my skis. If you're freehanding a lot of your mounts like I do, I think it's well worth your money.

As for the screws, you'll need a different screw with a different pattern. I believe it's a machine screw. I've used ones from home depot before, but it's honestly a PITA sometimes if you have to grind them down. BF has a list of the appropriate lengths and head diameters, I would recommend getting them. It's also usually worth it to have 1-2 extra of each unique length/diameter screw.

Sent from my Redmi Note 8 Pro using Tapatalk

-

01-02-2021, 11:45 AM #4494

Registered User

Registered User

- Join Date

- Dec 2009

- Posts

- 365

1) Correct you need machine screws for inserts. Binding freedom has a good selection. Profile of head is key. Length can be adjusted with a grinder if required.

2) I have that drill guide and really like it. Not really required for standard mounts, but really nice for drilling insert holes that need to be pretty well bang on. Also use it as a mini square to gauge tap plumbness while tapping insert holes. Works great and would recommend.

-

01-02-2021, 11:47 AM #4495

^^^Thx both. Yes, I'll get their screws (seems safer/easier) and prob load up on all the tools (guide, punch, etc). Still glad I've got a broken ski to practice on!

-

01-02-2021, 03:10 PM #4496

Insert questions pop up on various threads - mostly about what length screw to buy.

First though, both BF and QK use M5 x .8 screws. The thread pitch (.8) is the more common of the two M5 pitches, and if you're buying screws from other sources (i.e. McMaster Carr), they'll typically state this.

Specifying screws outside of the QK/BF universe isn't rocket science, although you won't find posi-drive screw heads if that's important to you.

Determining the length you need:

The question that always pops up is "what length screw for binding-X", coupled with "I'm going to add a 6mm toe shim, so how should I adjust this number?".

In the spirit of teaching a man to fish, and driven by the fact that I've found the occasional error on the BF site, I measure my own screw length spec.

Back when I was foolish enough to buy some Pivots (flame me now ), I noticed that the BF heel screw spec (I think the longer pair) was on the short side. When measuring, I ended up (and this is from memory) with 24mm screws that I shortened to 22mm (the choices in this length were either 20 or 24).

), I noticed that the BF heel screw spec (I think the longer pair) was on the short side. When measuring, I ended up (and this is from memory) with 24mm screws that I shortened to 22mm (the choices in this length were either 20 or 24).

My point is that I'd rather trust my ability to measure this stuff than risk a typo or other error on someone's website.

You need to know two things:

- How much exposed screw thread (below the binding) will inserts accommodate? Answer: a touch more than 5mm.

- How do you measure the screw length? See below ...

The inserts will accept a touch more than 5mm of screw thread, but you can squeeze a slight bit more if you drive the insert slightly below the level of the topsheet. Of course, this doesn't change how much thread you can engage, but rather how long a screw you can use without it bottoming out. This may or not be useful, but it's worth mentioning.

Note that the screw is at full strength if you engage 3 threads (machinist's general rule of thumb for this size screw), so if you engage 4mm of screw, you're plenty fine.

So, with this information in hand, use the screws supplied with the binders, and observe how much below the binding bottom they project (likely quite a bit more than 5mm). Measure the screws, and adjust accordingly to establish a length within the 5mm window (taking any added shims into account).

How screw length is measured:

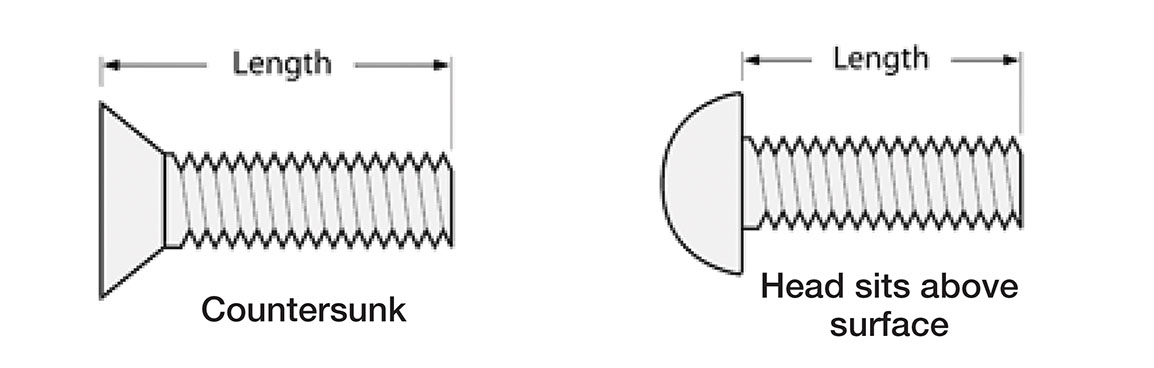

Lastly, the majority of screw lengths are specified two different ways. I'll leave it to your Googling skills to get more information (and about the exceptions), but here's one drawing to get you started.

For our purposes, these are the two most common ways of measuring screw length, and are generally divided into two categories: countersunk flat heads and all others. One variant to note is countersunk oval heads. They're measured from where the edge of the countersink contacts the surface (think of filing down the screw until it becomes a flat head):

... ThomGalibier Designcrafting technology in service of music

-

01-02-2021, 04:17 PM #4497

^^^Also super helpful, will be sure to double check the lengths

-

01-02-2021, 04:53 PM #4498

Registered User

Registered User

- Join Date

- Nov 2018

- Posts

- 757

-

01-02-2021, 05:12 PM #4499

Very timely. Good one Thom. Nice to have the confirmation on how theyre measured as well as how deep they go into inserts. I was running on 6mm but my inserts were probably driven in the ski a touch extra to allow 6mm out of the bottom of the binding.

It is best to get them longer and just cut them shorter to perfection. I have a nut for machine screws i put on the screw befor i shorten the screw with a hacksaw. So far just removing the nut after the cut has cleaned up the start of the threads for them to screw straight into the inserts

Im going to try inserts for my cast set up but im waiing on the drill bits and insert thread tap that fit my jigarex. Inserts should take up the gap , in the now, splayed toe holes and i want those inserts perfectly vertical and the perfect length. Heads dont look like they be much of an issue as long as they have some countersunk bevel. The afd is a good few mm higher than the screws so the boot sole wont be close to any screw head

Sent from my SM-G950W using TGR Forums mobile app

-

01-02-2021, 05:41 PM #4500

Thanks for bringing the nut up for cleaning up the thread after shortening screws. I meant to mention that. Indeed, when in doubt buy longer and saw/file to length.

You know the trick of installing the binding while the epoxy is curing? This is to nudge the screws even closer to dead on vertical. I've been hesitant to do this, for fear of there being some epoxy down in the insert and not being able to remove the screws. I finally gave it a go (super careful about keeping epoxy out), and it works. I don't tighten to binding mount torque, so as to not risk stripping the threads in the ski core.

With CAST (toe), I assume you mount the plate and one of the two toe pieces, since that's the most touchy of alignment issues.

I've found that even if you drill a perfectly vertical hole, you can mess it up (tilt) when tapping, so a tapping guide is key to a vertical hole.

... ThomGalibier Designcrafting technology in service of music

Reply With Quote

Reply With Quote

Bookmarks