Results 4,151 to 4,175 of 6863

-

11-28-2020, 09:40 PM #4151

Sick Day 114 w/ Fritschi Tecton

Second Tecton mount using inserts and the Powder Guide template. Went pretty smoothly but got I my first insert spinner. Either did a shitty job tapping or found soft spot. All the other holes went just fine. I ended up cramming the insert in there with a lot of gflex. It feels solid and I figure I can always replace with a rescue insert if I really want to. Can't wait to get these on snow!

-

11-29-2020, 08:22 AM #4152

-

11-29-2020, 08:31 AM #4153

Any tricks to sharpening bits?....besides buying new ones.....which I usually just do to start a season at our shop. (have had some 4.1/9.5 on SVST back order for all our metal sticks since Sept.)...

-

11-29-2020, 08:40 AM #4154

Hone them with your sharpening stones. If it's super dull, take it to grinder, go slow.

-

11-29-2020, 07:26 PM #4155

PSA: Mount your own fucking skis.

The kid’s K2 Marksman and some SPX bindings. Used the PX/Axial paper template from this thread. Love the Wintersteiger bit. Plugged the old holes with plastic plugs with wood glue.

He skis them tomorrow. Hopefully they all stay together.

Oh yeah: I also made sure they will fit my boot too, which is a mondo size smaller, cause I wanna try them. Nearly impossible to get a shop to make sure a ski will fit two boots, so another bonus of mounting your own fucking bindings.

-

11-30-2020, 04:48 AM #4156

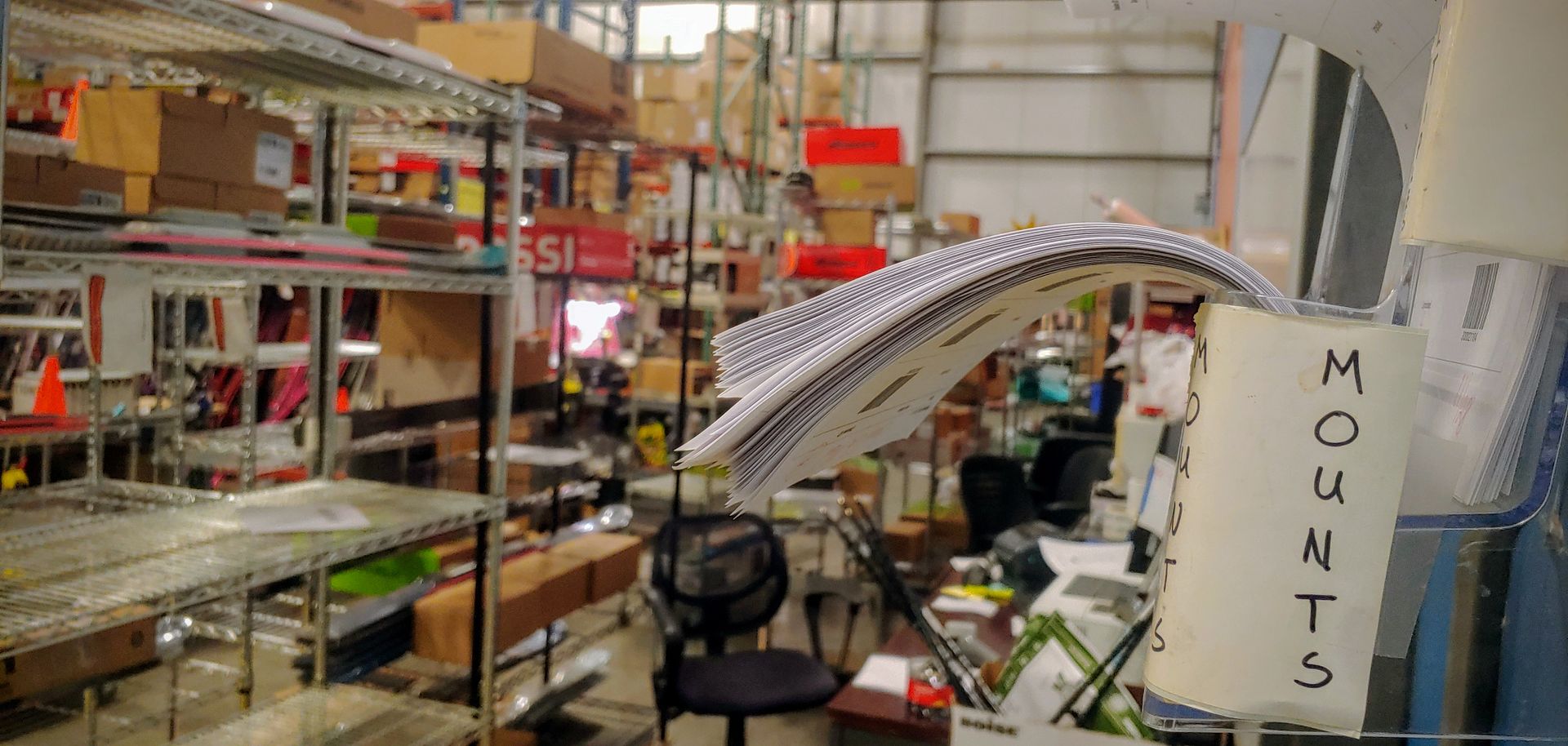

couple hundy in the que today

send reinforcements"When the child was a child it waited patiently for the first snow and it still does"- Van "The Man" Morrison

"I find I have already had my reward, in the doing of the thing" - Buzz Holmstrom

"THIS IS WHAT WE DO"-AML -ski on in eternal peace

"I have posted in here but haven't read it carefully with my trusty PoliAsshat antenna on."-DipshitDanno

-

11-30-2020, 10:27 AM #4157

I have some 182 Woodsman 108s that were mounted once. Seller said 305 bsl on the line for FKS so I was planning to re-use the holes. Ended up with a spinner in the heel. I also discovered that it really wasn't a 305 on the line and the mount is a good 7-8mm shorter. The binding adjusts to fit my boot, but I have two of the marks on the FKS adjusters showing and pretty close to the 3rd but seem to be able to get appropriate forward pressure. I can't remember if there is a max extension point on those?

After the spinner I kind of figured I'd just go back 10mm and not fuss with using that hole. That's when I realized the mount was short because I marked out -10mm with my template and the front holes are only 7.5mm from the template marks (center to center) and the heel has more clearance from old holes. Is 7.5mm center to center too close? Should I just take it -13 or 15mm from the "line" to be safe? My preference is to keep this as close to the line as possible, but when I look at the difference between -10mm or -15mm it surely can't make much on snow difference right?

So my options are epoxy the spinner and use existing mount, mount at -10mm from the line leaving only 7.5mm center to center with existing toe holes (epoxy/wood dowel existing holes?), move the mount back so I have at least 10mm center to center with existing holes (end up at 13-15mm behind the line.

-

11-30-2020, 10:40 AM #4158

So, with the existing toe mount location, your boot center ends up how far from the line? Keep that and only redrill the heels maybe?

Edited to add: If they were mine, and since the boot fits with correct forward pressure, I'd just fix the spinner and not put in any more holes.

-

11-30-2020, 10:58 AM #4159

Registered User

Registered User

- Join Date

- Mar 2008

- Location

- northern BC

- Posts

- 31,085

I would cram some slowset epoxy & chopped up FG/ steel wool/ filler of somekind into the spinner hole, run the screw in till its JUST about to spin and let the epoxy cure over night.

Crank the screw down in the AM and if it doesnt spin yer fixedLast edited by XXX-er; 11-30-2020 at 11:43 AM.

Lee Lau - xxx-er is the laziest Asian canuck I know

-

11-30-2020, 11:30 AM #4160

Registered User

Registered User

- Join Date

- Feb 2016

- Location

- Rossland

- Posts

- 136

-

11-30-2020, 12:10 PM #4161

-

11-30-2020, 12:22 PM #4162

The boot center is maybe a few mm's behind the line. Using the existing toes, the template shows about 7mm center to center between new location and old holes for the heel.

Is it a terribly bad idea to add the epoxy and FG down through the binding hole with the heel still in place? I'm a bit uncomfortable unscrewing the holes that had good bite and having to do it again. It's so easy to cross thread the holes especially the rear/deep ones in the heel.

-

11-30-2020, 12:47 PM #4163

Registered User

Registered User

- Join Date

- Mar 2008

- Location

- northern BC

- Posts

- 31,085

sure do it without removing the heelpiece

what i did was chop FG strands into 1/2" pieces, mix in the slow set but don't go too resin rich, cram the mixture into the hole, run the screw in stopping at about where it will spin, cure overnight

crank it down and if it doesnt spin ... it is no longer a spinner

others on tech talk have done this with sucessLee Lau - xxx-er is the laziest Asian canuck I know

-

11-30-2020, 01:27 PM #4164

-

11-30-2020, 02:06 PM #4165

Like how much material are we talking? Seems like there would be some concern of overpacking the hole and not getting the screw fully seated. It's tempting since there's not much to lose and I have all the material on hand. Worst case it doesn't work and I remount anyways.

As for pivot/FKS heel adjustment - is anyone aware of what the max recommended extension of the adjust arms on the heel piece is? Is there a downside to being at the back edge of the adjustable range? The template normally gets me partway between the first and second band on the arms.

-

11-30-2020, 02:11 PM #4166

Registered User

Registered User

- Join Date

- Dec 2010

- Posts

- 3,941

-

11-30-2020, 02:54 PM #4167

King potato

King potato

- Join Date

- Feb 2011

- Location

- BC

- Posts

- 1,951

-

11-30-2020, 02:56 PM #4168

Registered User

Registered User

- Join Date

- Mar 2008

- Location

- northern BC

- Posts

- 31,085

Mix up a glob the size of lets say half a sugar cube, wet out the FG, make it less resin rich is (stronger) get it wrapped around the screw, the screw will pull itself in there on what threads remain, stop screwing before it spins, crank the screw down hard the next day after it cures

if you got all the stuff you got nothing to lose

a number of people here on tech talk have done it,

or you could pay $ to get a helicoil or move it completeley but this will probably be the easiest and cheapestLee Lau - xxx-er is the laziest Asian canuck I know

-

11-30-2020, 03:29 PM #4169

-

12-02-2020, 10:06 AM #4170

Sorry if this has been discussed before why do they only recommend tapping holes for skis with metal top sheets? Seems like you can get a stronger mount for tapping any skis. Any disadvantages for tapping non-metal skis?

-

12-02-2020, 10:11 AM #4171

I think there is definitely some benefit to tapping, but the debate seems to be whether or not it’s worth it or even necessary. I’ve never tapped my holes and have never had any issues over dozens of skis in my life. Most shops don’t tap unless required from what I can tell.

That being said, if you have the tools and the time, it can give you a little bit more insurance.

-

12-02-2020, 10:43 AM #4172

You'll get a tighter thread by not tapping. The screw will deform the hole to its exact shape. The other risk is ensuring you get the threads started correctly on a tapped hole. With metal it's going to be harder to cross thread the hole while installing the screw, but it's pretty easy to mess up when installing a screw in to a tapped hole when it's just fiberglass/wood threads.

-

12-02-2020, 04:23 PM #4173

Registered User

Registered User

- Join Date

- Mar 2008

- Location

- northern BC

- Posts

- 31,085

any hole with existing threads or a threaded hole if you turn the screw in the hole backwards by hand with just the bit you can feel the screw dropping the threads

i used to do this to swap DIN/AT soles on Garmont Endorphins, 9 screws for each boot into plastic and never had a spinner

I have never tapped binding screws either and the world hasnt ended

altho we now have covid ?Lee Lau - xxx-er is the laziest Asian canuck I know

-

12-02-2020, 04:39 PM #4174

-

12-02-2020, 05:09 PM #4175

Registered User

Registered User

- Join Date

- Nov 2016

- Posts

- 1,409

Reply With Quote

Reply With Quote

Bookmarks