So I just received my brand new 08/09 legend pro's and there's a base patch on one of the skis!!!????

I would have thought this should have, at least, been sold as a blem pair and not for full price.

Additionally, I was looking forward to putting the first holes in these myself. Not have the factory beat me to it.

I'm kinda disappointed.

Edit: The tip of the other ski makes a creaking noise when I flex it. Like it's de-laminating internally.... Having a well set base patch is one thing but now I'm worried. Does anyone have any experience with 'creaking skis'? Is it normal and I've just never come across it before?

Results 1 to 25 of 26

Thread: 08/09 Legend pro production WTF

-

04-23-2008, 03:47 AM #1

08/09 Legend pro production WTF

Last edited by jerr; 04-23-2008 at 05:01 AM.

Nine out of ten Jeremy's prefer a warm jacket to a warm day

-

04-23-2008, 05:06 AM #2

send them back. seriously.

-

04-23-2008, 05:40 AM #3

Obviously a defective pair.

The patched base is indeed very strange. Who did you get those skis from ?"Typically euro, french in particular, in my opinion. It's the same skiing or climbing there. They are completely unfazed by their own assholeness. Like it's normal." - srsosbso

-

04-23-2008, 05:54 AM #4

Not telling. The shops been really good to me and I haven't discussed this with them yet. I'll give them the chance to sort it out should I decide to go that way. Besides, they were in plastic and you'd never have know until they were un-wrapped and studied.

Having gone back to the ski and repeated flexed the tip (in disbelief/despair) they've stopped creaking. I'm wondering whether this is a natural 'settling' of the lamination? This certainly isn't reassuring but maybe it'll be ok....?

The base patch is damn weird/disappointing though?

Edit: This hombre is in NZ and the skis were 'interneted' from the US. Sending them back is a major that I'd rather avoid. If I can suss out what's happening then I'll know if I have to or not.Last edited by jerr; 04-23-2008 at 06:04 AM.

Nine out of ten Jeremy's prefer a warm jacket to a warm day

-

04-23-2008, 06:10 AM #5

^Just asking if they came from a "legit" source or some grey market seller.

Because I'm really surprised Dynastar sells a ski with a repaired base.

The delam issue is different. I understand how it can get un-noticed until the ski is actualy skied.

Anyway, send them back, indeed. I've never heard of creaking skis..."Typically euro, french in particular, in my opinion. It's the same skiing or climbing there. They are completely unfazed by their own assholeness. Like it's normal." - srsosbso

-

04-23-2008, 06:13 AM #6

From a well known shop

Last edited by jerr; 04-23-2008 at 06:16 AM.

Nine out of ten Jeremy's prefer a warm jacket to a warm day

-

04-23-2008, 07:38 AM #7

The creaking noise when flexing the tip is something I have experienced on old LP's and the 2009 models. I don't think its a big deal and I have not noticed any problems.

The "Repaired Base", however troubles me. No new ski should have a patch on its base.

Can you post a pic?

-

04-23-2008, 08:30 AM #8

-

04-23-2008, 08:57 AM #9

First time I flexed my 08 LPs and 08 Watea 94's out of the box I heard a creak/crack or two, but nothing after that. It's probably just a function of the materials having more time to cure/break-in. I would be really pissed about the patch - I'm super picky though and have been known to obsess over much smaller stuff than that (something I need to work on). Thanks for posting this, makes the decision I outlined in this thread a little easier:

http://www.tetongravity.com/forums/s...d.php?t=120793

-

04-23-2008, 10:44 AM #10

Almost all new skis will creak or crack the first time you flex them. When I worked in a shop we flexed every ski that came out of a box before it went on the floor because clients got scared when they flexed a ski and it cracked. I think it has something to do with the resins used during manufacturing. Maybe Splat can coment on this.

-

04-23-2008, 12:47 PM #11

-

04-23-2008, 01:47 PM #12

-

04-23-2008, 03:18 PM #13

new ones are a touch softer and 3mm wider all over

-

04-23-2008, 04:27 PM #14

one-track mind

one-track mind

- Join Date

- Jul 2004

- Location

- Truckee

- Posts

- 2,325

I don't think the OP meant drilled holes.

RE: quality control for Dynastar's "channel" construction skis (all XXLs, next year's LP's): I posted here after I closely inspected 8 pairs of 1st-year XXLs from SAC. Granted, all skis have microflaws if you look close enough, but old LP's seemed exceptional (admittedly, I fondled only 2 pairs of old LP's). Anyway, 3 of 8 pairs of 1st-year XXL's had factory-repaired ptex gouges, and a 4th pair had unfortunate graphics flaw, so only 4 of 8 would be considered "great non-blems".

Not complaining, just saying beware and inspect before buying if you can---the days of high quality control LP's are likely over. I think most people would be bummed about those 3 pairs which, in addition to the ptex repairs, had other flaws that increase disappointment: like 2" long protruding fold/ripple in topsheet material near edge, topsheet coat dimpling/lumpy near edge, significant gaps at tip and tail seams (epoxy would solve that), and an unfortunate sidewall ding near tip (live with it). The 4th pair with graphics flaw was hard to ignore, because although small, it was in the most prominent part of the tip area---would likely disappoint someone if they paid close to retail price. Hmmm...I guess it's possible that SAC is not a fair sampling (maybe higher rate of flaws in the pairs leftover after sales by backcountry/tramdock).

On the bright side, I have not heard of any durability issues yet for any good or flawed "channel-construction" Dynastar skis---just possible disappointment when you unwrap your brand new skis.

.Last edited by Vitamin I; 04-23-2008 at 04:36 PM.

- TRADE your heavy PROTESTS for my lightweight version at this thread

"My biggest goal in life has always been to pursue passion and to make dreams a reality. I love my daughter, but if I had to quit my passions for her, then I would be setting the wrong example for her, and I would not be myself anymore. " -Shane

"I'm gonna go SO OFF that NO ONE's ever gonna see what I'm gonna do!" -Saucerboy

-

04-24-2008, 03:32 AM #15

08/09 fit my quiver better. I've got titan pro's (little cut, 96 waist, 193 long and beyond stiff) for hard charging. I wanted something to slot between them and 05 gotamas.

The photo thing fell off todays radar I'm afraid. We were way to busy and I couldn't be arsed at the end of the day. So here's a description - It's 15cm from the tail, on the edge, ~ 20 x 20mm, irregularly shaped straight edges and was done before the pattern was put on the base. It's ridiculously hard to notice. I only found it because there was a tape marker on the top sheet that made me study the area.

To be honest, having thought about it, it won't effect the performance of the ski or my enjoyment of it. It just kinda pissed me off a the time - new toys et al. It is interesting to realise, though, that this is probably a pretty common industry practice, just rarely noticed.

So - if the patch falls out I'll be upset. If the rig delams I'll be upset, but otherwise I'm just going to enjoy the hell out of them in between my titan pro's and my gots.

Thanks for the replies/comments. Particularly the one from the shop flexing guy. Much appreciated.Nine out of ten Jeremy's prefer a warm jacket to a warm day

-

04-24-2008, 04:15 AM #16

Registered User

Registered User

- Join Date

- Feb 2007

- Location

- auckland, nz

- Posts

- 49

it's always a worry when you're spending so much on freight, but I have had some quality issues with a couple of shipments - one shop was straight up and sent a full replacement and apologised profusely, another shop pissed around for ages and then sent a replacement, while the third one said tough luck.

ymmv

-

04-30-2008, 07:49 PM #17

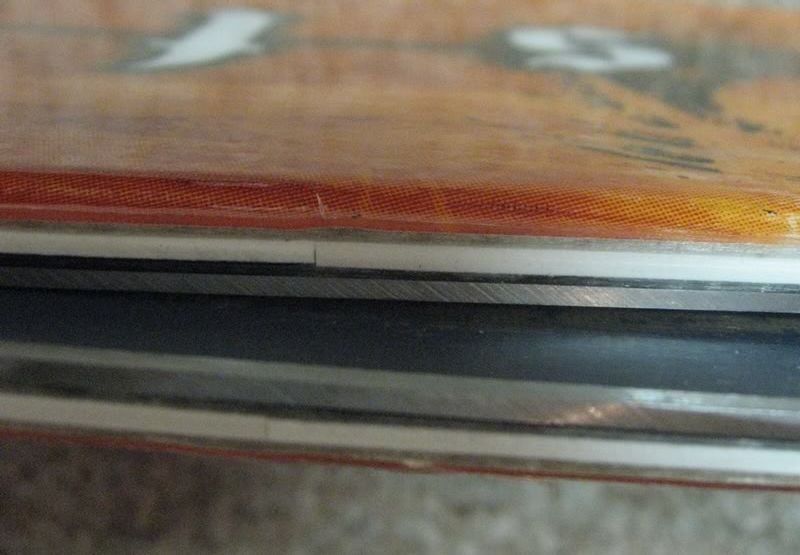

Snapped some pictures of something I thought was a little unusual about my 08/09 LP's. This is a shot of where the ABS sidewall of the ski edge meets the ABS used in the tip.

right edges (anyone else reminded of techtonic plates?):

left edges (much nicer):

According to the shop I bought these from, all of their 176's are this way. I am contemplating returning them because I kinda feel this is an unnaceptable defect for a $900 ski, although I should have caught the defect before they were mounted... and skied.

-

04-30-2008, 08:38 PM #18

Registered User

Registered User

- Join Date

- Dec 2005

- Posts

- 3,609

-

04-30-2008, 09:00 PM #19

to answer your question, I sure as hell didn't pay $900, but the MSRP is somewhere in that neighborhood, and I'd expect better quality control for that price.

-

04-30-2008, 09:40 PM #20

Lots of people like me have access to a shrink wrapping machine..."In plastic" doesn't mean that much to me.

But jerr I like your style. I just bought a pair of hiking boots from a reputable dealer. One is clearly a centimeter short of the other in height. But I don't think I will notice when they are on my feet, so I am just going to give it a go. Try to document your skis in pics before you beat them up, so you can show where the patch was when they were pristine. Then there will be no question later if this was your own damage repaired.

-

05-01-2008, 12:19 AM #21

Registered User

Registered User

- Join Date

- Feb 2004

- Location

- SF, CA

- Posts

- 838

Any ski will make a creaking (more of a stretching) sound when flexed for the first time after curing. It's normal as long as it's only the first time it's deeply flexed. If it continues to creak, something is wrong.

My XXLs looked great.

Base repair is weird though...

-

05-01-2008, 10:33 AM #22"We don't beat the reaper by living longer, we beat the reaper by living well and living fully." - Randy Pausch

-

05-01-2008, 10:43 AM #23

BALLS>talent

BALLS>talent

- Join Date

- Jan 2008

- Location

- Los Angeles

- Posts

- 376

-

05-01-2008, 10:59 AM #24

-

05-01-2008, 01:06 PM #25

my 194's have looked like that since I bought them 100 ski days ago. Actually I sold that pair, but my new ones look exactly the same.

Similar Threads

-

legend pro rider....07/08or 08/09???

By badreligion in forum Tech TalkReplies: 13Last Post: 04-12-2008, 09:27 AM -

?'s about 08/09 legend pros

By huckfinn in forum Tech TalkReplies: 5Last Post: 03-27-2008, 10:27 AM -

dynastar legend pro rider 07/08 or 08/09???

By badreligion in forum General Ski / Snowboard DiscussionReplies: 4Last Post: 03-24-2008, 08:15 PM -

Dynastar Legend Snowbird 11000?

By CaddyDaddy77 in forum Tech TalkReplies: 11Last Post: 02-02-2005, 10:42 PM -

2004 Dynastar Legend Pro: News from the rep

By phUnk in forum Tech TalkReplies: 55Last Post: 01-21-2004, 05:27 PM

Reply With Quote

Reply With Quote

Bookmarks